Multifunctional surface treatment systems

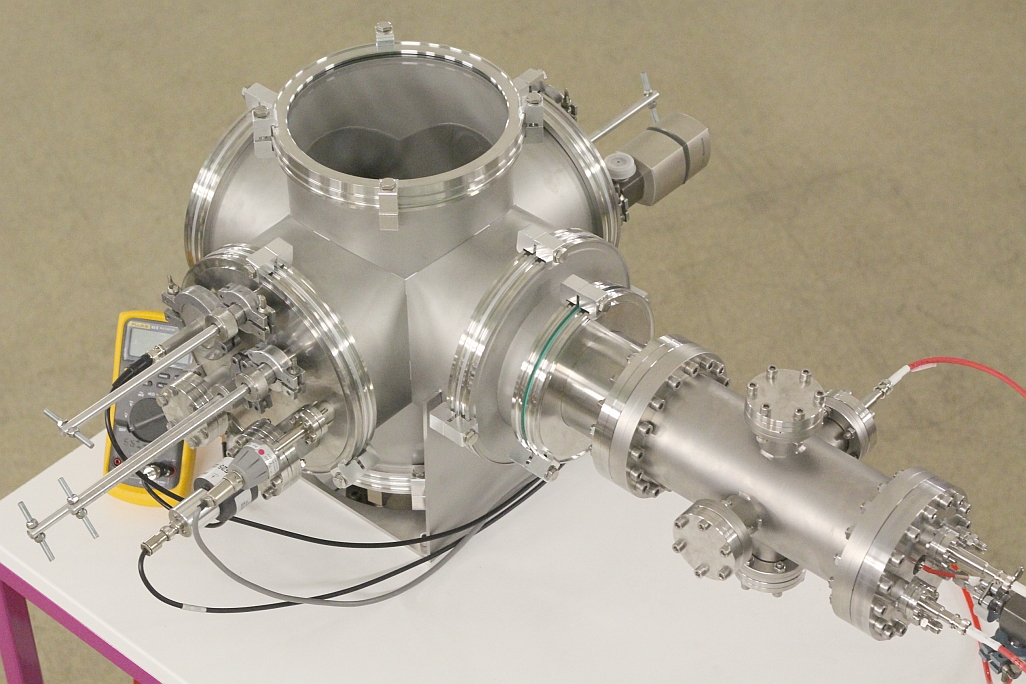

One ion source, multiple surface treatments. Polygon Physics offers a package deal for R&D purposes: a single system with which you can do a series of surface processing steps on the same sample without having to breaking the vacuum.

Multiple surface processing steps in one compact R&D system

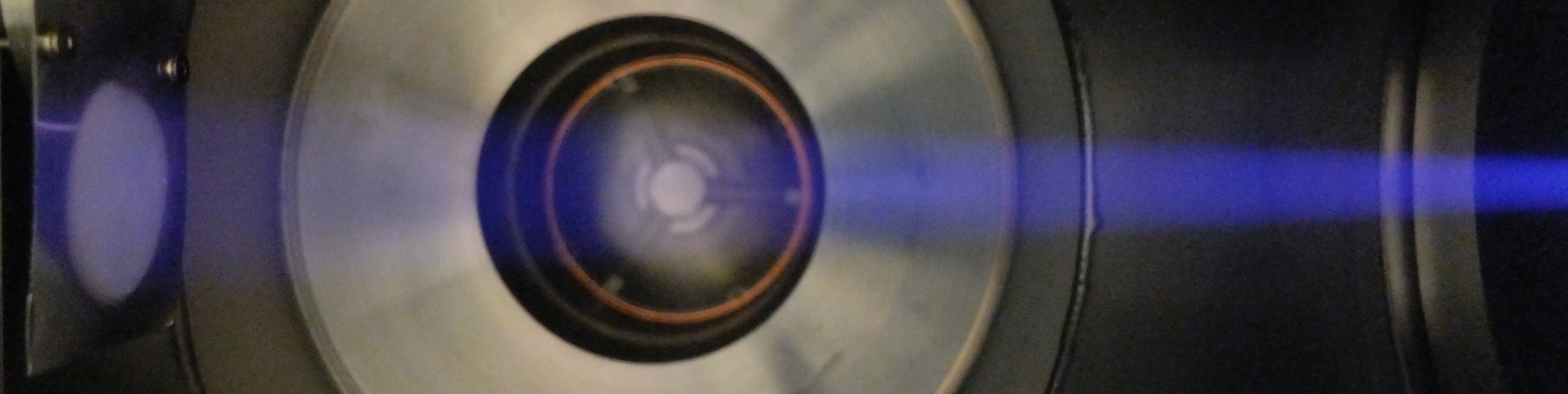

ion beam sputter deposition

multilayer depositions possible (two different sputter targets)

sputter cleaning

e.g. for improved adhesion of thin films

nanostructuring

to change the surface properties (e.g. absorption, decorative, adhesion)

low energy ion implantation

up to 30kV

Clean your sample before thin film deposition, nanostructure its surface before protecting it by a top coating, deposit two thin films of different material, all is possible with our multifunctional surface treatment system.

The system offers a high flexibility in process parameters:

- large operating window for the ion souce in terms of beam energy, ion current, and beam shape

- sputter target and film thickness monitor mounted on rotating and retractable axes

- sample mounted on a rotating and retractable arm of adjustable length for the different process modes

One system, different operating modes

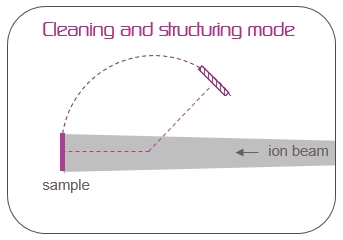

Sample cleaning and nanostructuring mode

The sample is rotated into the beam path. The sputter target and Film Thickness Monitor are retracted.

Beam calibration mode

The sample is rotated out of the beam path. The target and film thickness monitor are retracted. The beam is allowed to enter the Faraday cup without any obstructions to measure the beam current and calculate the average current density on the sample.

Thin film deposition mode

The target is placed in the beam path. The sample is in its deposition position. The Film Thickness Monitor is retracted.

Deposition rate calibration mode

The target is placed in the beam path. The sample is rotated to the deposition position. The Film Thickness Monitor (FTM) is placed between the sample and the target.

La conception de la machine Multitraitement est cofinancée par l’Union européenne. L’Europe s’engage en Auvergne-Rhône-Alpes avec le Fonds européen de développement régional.