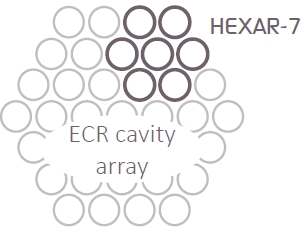

HEXAR | Broad Beam ECR source

Source principle

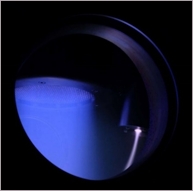

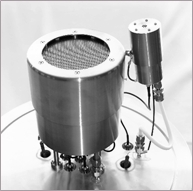

HEXAR is composed of an hexagonal arrangement of mini microwave cavities that each operate an ECR discharge at ultra low RF power (a few Watts per cavity at 2.45 GHz). This approach is successful because of the reliability and stability of the ECR plasma, and the fact that the source has no consumables. In addition, it enables control over the current density profile of the beam, in a way inaccessible to standard broad beam sources.The current density profile can be varied both in shape and in amplitude through the combination of gas flow, optics, and applied RF power.

Scalable technology

HEXAR relies on a scalable principle: the surface area that can be processed increases with the number of cavities that is used. Contact us if you are interested in ion processing of larger surfaces. You can also take a look at our custom beam solutions page for other possibilities enabled by our multi-cavity approach.

Neutralizer

For ion processing of non-conducting substrates a neutralizer can be used to avoid surface charging.

Polygon Physics offers an ECR electron source as neutralizer, which has no consumables like filaments. This neutralizer is based on the same compact ECR technology as HEXAR and is built from a single microwave cavity that is powerful enough to completely compensate the positive ion current.

Applications

Different applications required different beam properties. The HEXAR broad beam ECR source can be tailored to different applications by adapting the beam optics and varying the applied RF power per cavity, but can also be customized to specific sample sizes early in the design phase through the number of cavities that constitute the source. Typical applications are

- etching

- cleaning

- surface modification

- ion assisted deposition

- ion beam sputter deposition

More general information on these applications can be found on this page.

Technical data

The source module is delivered with 19¨ rack mount electronics, SMA and HV cables, power cord and USB software. Not included are the source gas, source cooling system (Swagelok 6mm), and pc. HEXAR can be tailored to your specific needs. Contact us for the possibilities and/or check our page on custom beam solutions.