Custom beam solutions

Ion source, electron source, plasma source, atom source

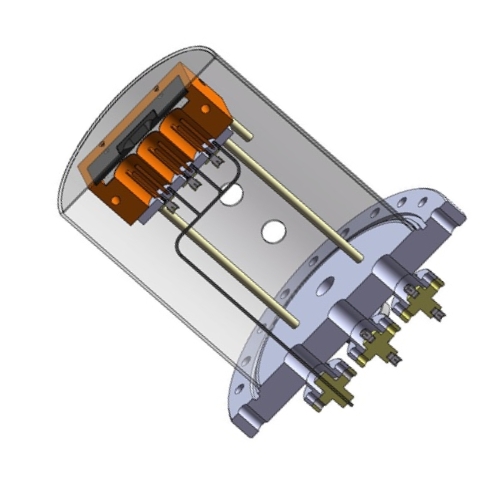

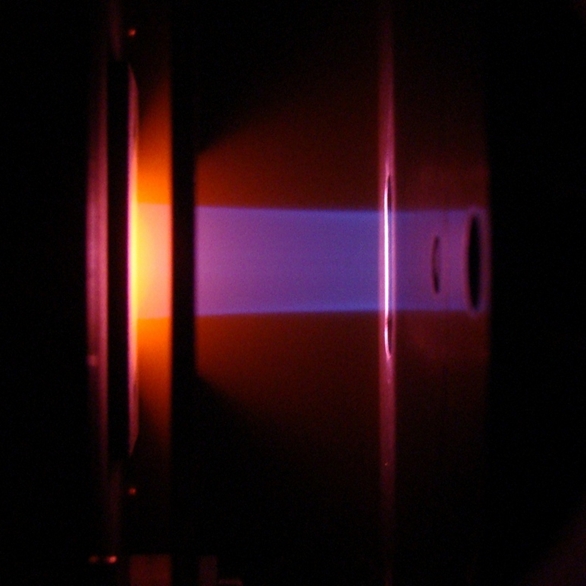

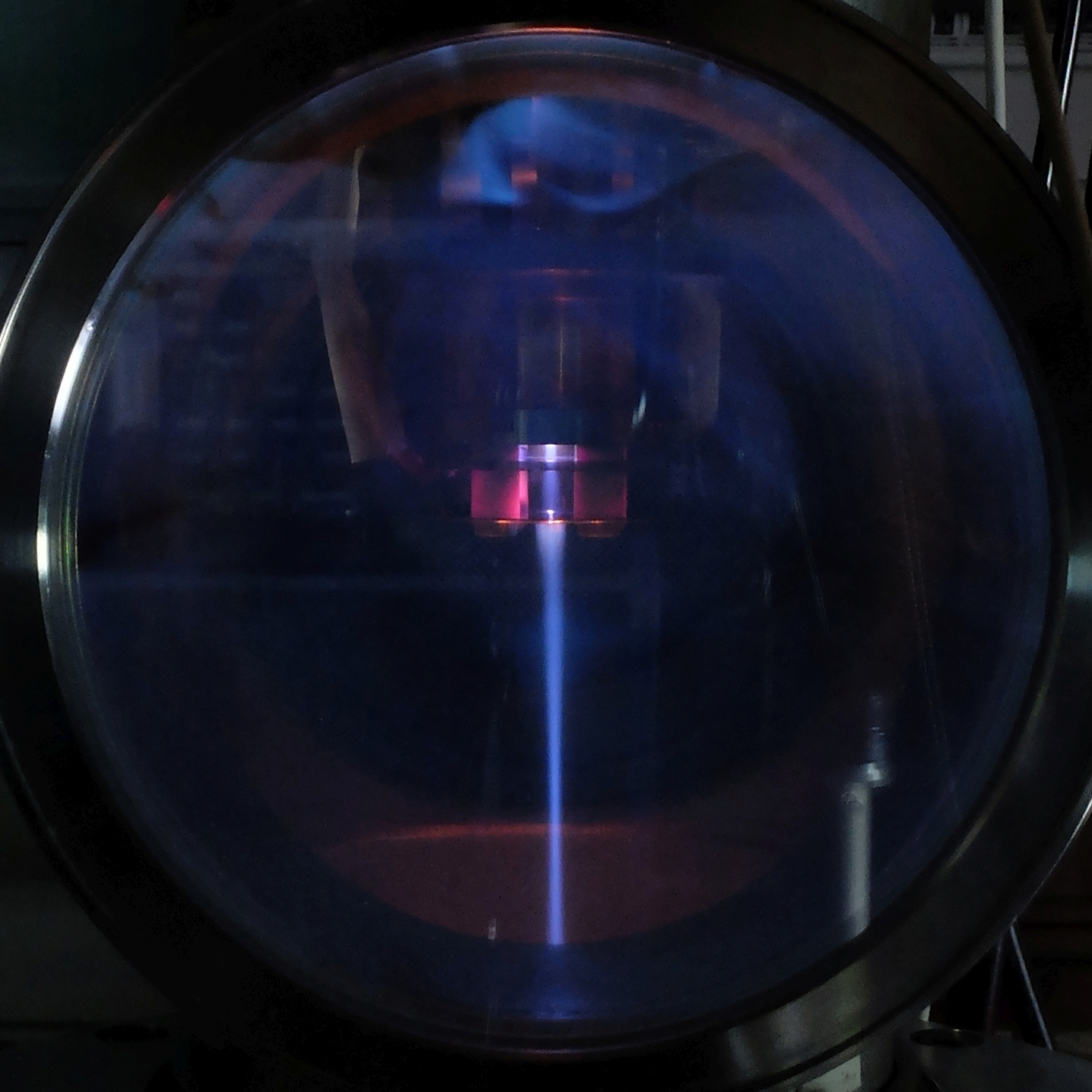

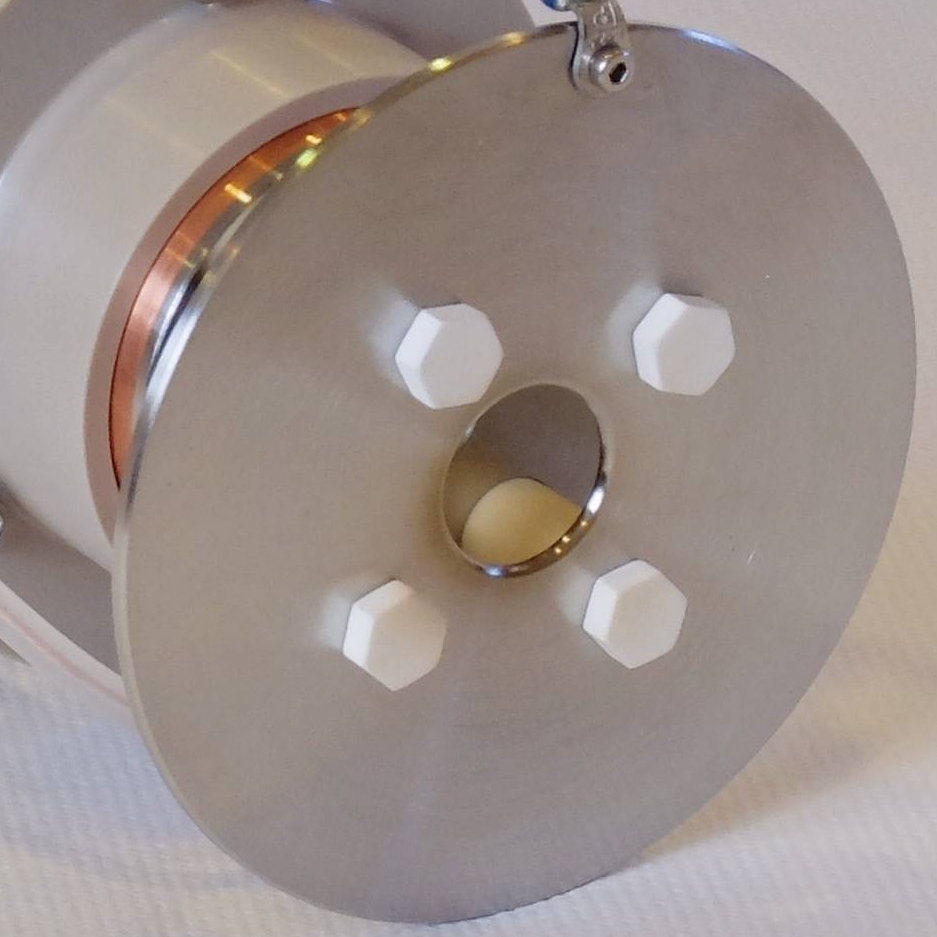

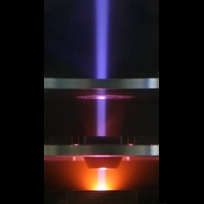

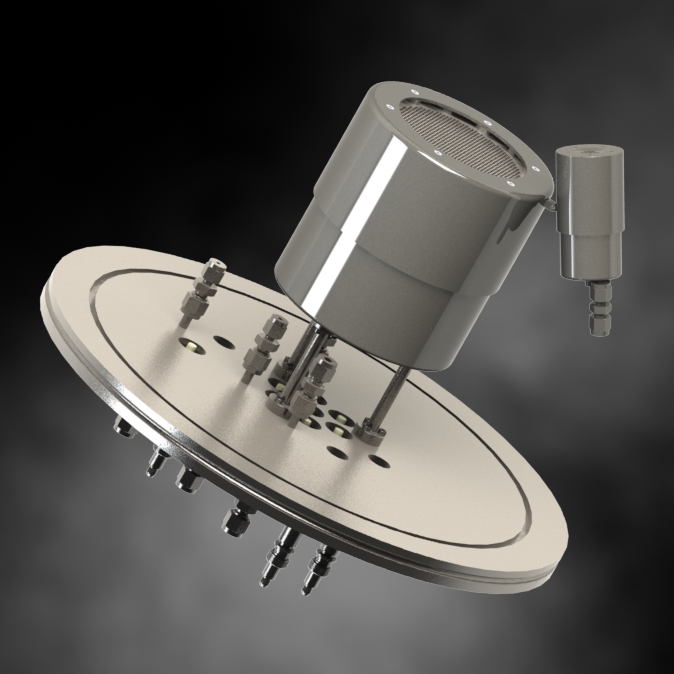

Our ECR plasma cavities can be configured to operate as ion source, electron source, plasma source, or atom source. This is a matter of adapting the extraction optics, changing the bias, and/or in the case of an atom source, adding deflectors to capture the charged particles. The extraction can be by grids or by aperture electrodes.

The pressure inside the plasma cavity must be large enough to maintain the plasma and is elevated with respect to the chamber pressure. The chamber pressure during source operation will depend on the system: base pressure and pumping capacity, and the source parameters: the gas inlet and the size of the extraction hole(s).

For single cavity sources the minimum flange size has an inner tube diameter of 35mm and the source head can be supported by the flange, or mounted anywhere you want inside your system with only flexible cables to the flange. Both High Vacuum as well as Ultra High Vacuum (UHV) compatible sources are possible.

TES sources are based on our smallest cavity, and can be configured for different beam types and shapes. Take look at our larger IE-gun if you are interested in high energy applications, or contact us for other possibilities.

ECR stability and reliability

no hot filaments

extraction optics adapted to your application

flexible source mounting

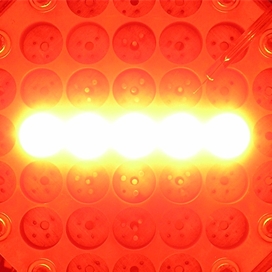

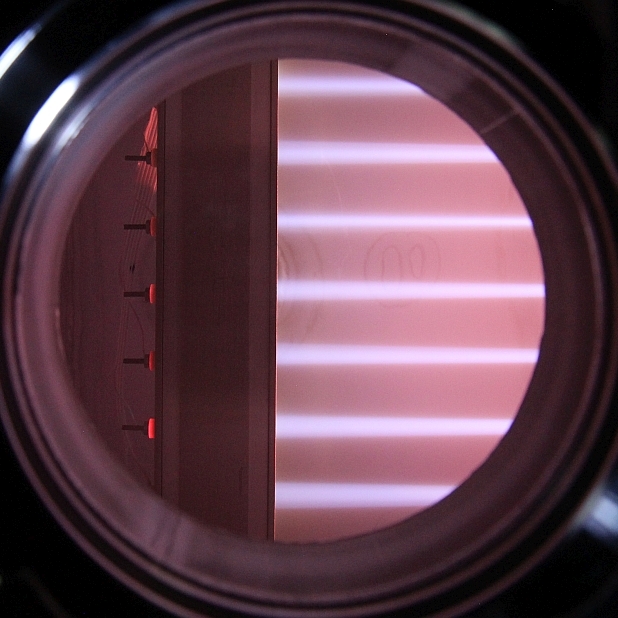

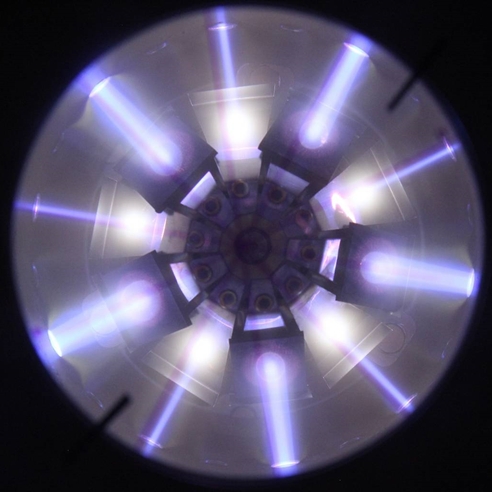

Large beams from multiple cavities

By grouping multiple of our ECR plasma cavities together, we can make beams of basically any size, and also beams with a shape other than circular, like linear or rectangular. Unique for such multi cavity solutions is that the internal current distribution of the beam can be controlled. This is because each cavity has its own power supply for the microwave. Such large beams are typically used for ion assisted deposition, sputter cleaning, nanostructuring and ion implantation at industrial scale.

Beams based on twenty cavities are already reality (industrial prototype; linear beam), and we have recently developed the broad beam source HEXAR-7 (circular beam). For the moment we consider sources with several tens of cavities as feasible. This brings us up to the meter range in terms of beam size. Contact us if this is of interest to you.

Linear beams

Meter sized beams

controlled current density distribtion

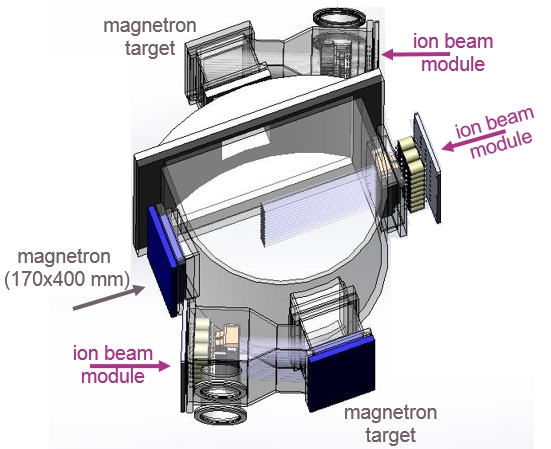

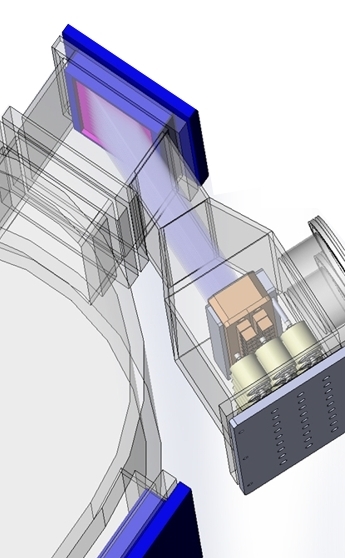

Multiple individual beams in one vacuum system

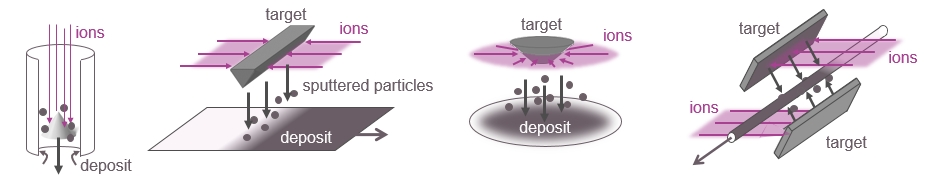

The small size of the plasma cavities enables the possibility to place multiple of them rather freely inside a vacuum system. This opens possibilities for example for 3D surface processing, with multiple beams under different angles. It also enables batch processing of multiple samples at the time without beam overspill, and has enabled the development of a new thin film deposition method based on multi beam sputtering.

3D surface processing

batch processing of multiple samples at the time

multi beam sputter deposition

Beam solutions for different thin film deposition geometries

Where a geometry with a circular array of sources is adapted to circular samples (conical target base), a linear geometry with a line (or multiple lines) of sources and a rectangular sputter target is more suitable for rectangular samples and roll-to-roll applications. Another possibility is top-bottom deposition using two opposing linear sputter deposition modules (beam plus target) which can be useful for coating both sides at once. A special case is thin film deposition on the interior of tubes. With our technology we can coat the tubes from the inside, simply by adapting beam and target to the tube diameter. Ask us for the possibilities.

circular samples, one side

rectangular samples, one side

two side deposition

tube interior deposition

Retrofitting

The concept of little building bricks makes our technology very suitable to retrofitting existing systems. It is for example possible to replace the interior of a Bernas (Freeman) type ion source for ion implantation by an ECR ion source of exactly the same geometry. It is also possible to replace a magnetron sputter module by a multi beam sputter module of the same dimensions, or on for example a carrousel type system, to replace a magnetron module by an ion beam module for assistance, sputter cleaning, nanostructuring, or implantation. Contact us to find out if we can refurbish or upgrade your system to your liking.

replacement of other type ion sources

replacement of magnetron sputter modules